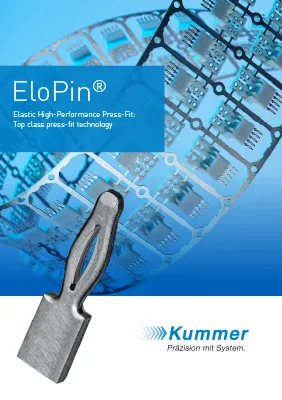

The EloPin® is the most reliable press-in technology for printed circuit boards. The EloPin® is a modified needle-eye press-fit zone which functions as a mechanical press-fit pin.

A number of variants are available for the solder-free EloPin® press-fit pins. With over 15 years of production experience, Kummer is one of the most experienced producers of these pins.

The EloPin® press-fit technology is a solder-free electrical connection technology for printed circuit boards (PCB). EloPins® generally find application wherever components are inserted into PCBs.

There are many application areas for the EloPin® such as:

- mechanical engineering

- automotive (electric vehicles)

- vacuum engineering (e.g. semiconductors)

- aerospace, medical engineering

- or clean-room applications

The EloPin® press-fit technology is a solder-free electrical connection technology for printed circuit boards (PCB). EloPins® generally find application wherever components are inserted into PCBs.

There are many application areas for the EloPin® such as:

- mechanical engineering

- automotive (electric vehicles)

- vacuum engineering (e.g. semiconductors)

- aerospace, medical engineering

- or clean-room applications

Click on the picture to download our "EloPin" brochure

- gas-tight, solder-free and vibration resistant connection

- various sizes (0.4, 0.6, 0.8 and 1.2 mm) available

- low insertion force for preservation of the perforated wall of the printed circuit boards (PCB)

- no formation of chips – therefore very good technical cleanliness

- high mechanical stability – lack of sensitivity during assembly

- problem-free functionality over the whole tolerance range of the PCB hole

- low mechanical stress on the PCB due to the press-fit process

- application area with temperatures from -40 °C to 150 °C, therefore well-suited to the automotive field

- gas-tight, solder-free and vibration resistant connection

- various sizes (0.4, 0.6, 0.8 and 1.2 mm) available

- low insertion force for preservation of the perforated wall of the printed circuit boards (PCB)

- no formation of chips – therefore very good technical cleanliness

- high mechanical stability – lack of sensitivity during assembly

- problem-free functionality over the whole tolerance range of the PCB hole

- low mechanical stress on the PCB due to the press-fit process

- application area with temperatures from -40 °C to 150 °C, therefore well-suited to the automotive field

Click on the picture to download our "EloPin" brochure

Optimised pin properties through improved manufacturing processes*. Experience makes the difference, also with the EloPin®. Because the pins are made by different manufacturers, they can vary in their properties.

Kummer has continuously improved and perfected the manufacturing process over the years. The Kummer pin is characterised by:

- adherence to very tight tolerances, process-safe even for the largest of series

- the high manufacturing precision of the complex 04 pin, which can be produced using the progressive injection moulding process.

*The EloPin® was developed and patented by TBS Sorig. Several companies manufacture this pin under licence, whereby only the function and shape are protected. The production process, on the other hand, is not prescribed

Optimierte Pin-Eigenschaften durch verbesserte Herstellungsverfahren* Die Erfahrung machts, auch beim EloPin®. Da die Pins von unterschiedlichen Herstellern gefertigt werden, können sie in ihren Eigenschaften variieren.

Kummer hat den Herstellungsprozess über die Jahre kontinuierlich verbessert und perfektioniert. Der Kummer-Pin zeichnet sich aus durch:

- Einhaltung von sehr engen Toleranzen, prozesssicher auch bei größten Serien

- die hohe Fertigungspräzision des komplex herzustellenden 04er Pins, der im Folgeverbund-Spritzverfahren hergestellt wird.

*Der EloPin® wurde von TBS Sorig entwickelt und patentiert. Mehrere Unternehmen stellen diesen Pin in Lizenz her, wobei lediglich die Funktion und Form geschützt ist. Das Produktionsverfahren hingegen wird nicht vorgeschrieben

A reliable connection

In order to adapt to the final hole diameter, during the press-fit process the EloPin® is subject to a single plastic deformation. Due to the special characteristics of EloPin® press-fit technology, after this plastic deformation a high elastic component remains. The high elasticity is decisive for the permanent maintenance of the contact pressure also under stress and therefore a reliable electrical connection.

Quick sampling for prototypes and pilot series

Through our own toolmaking shop, a quick reaction to implement prototypes is possible. This enables sampling with pins, in consultation with the R&D department of our customer, which are already manufactured under series conditions and therefore close to the later series part. This is an important consideration for the meaningful results of function and property tests.

100 % quality reliability

The small and large-scale production of the EloPin® is subject to 100% vision control. This ensures a continuously high reliability of the required functionality. In general, the EloPin® is qualified according to DIN EN 60352-5 with important parameters (temperature range, number of temperature cycles, etc.) included in an extended inspection plan.