Our strength is the ability to offer a complete solution including the tool up to the finished assembly. This is made possible by an experienced team of employees with many years of company service. They use their experience and expertise for the benefits of customers.

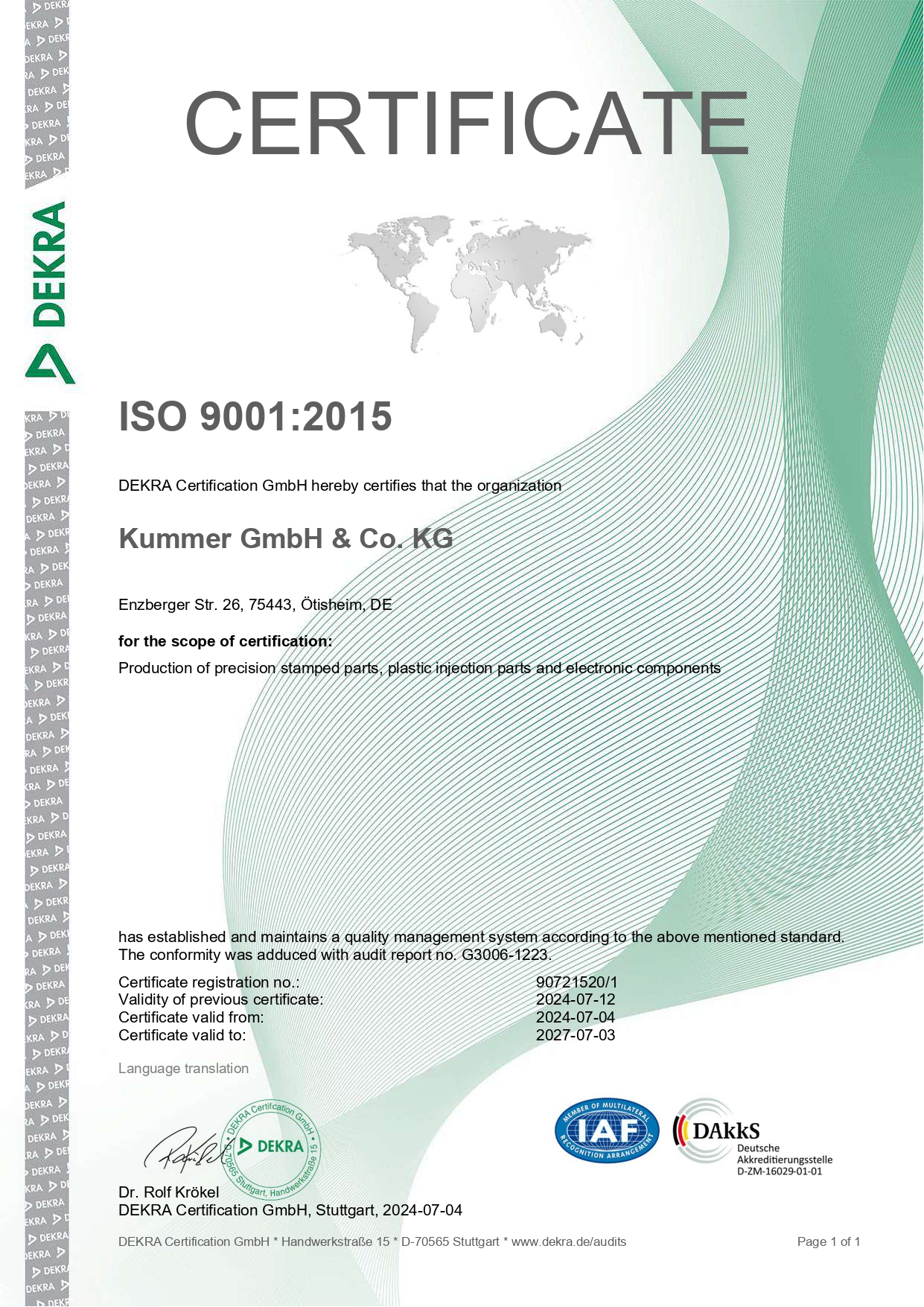

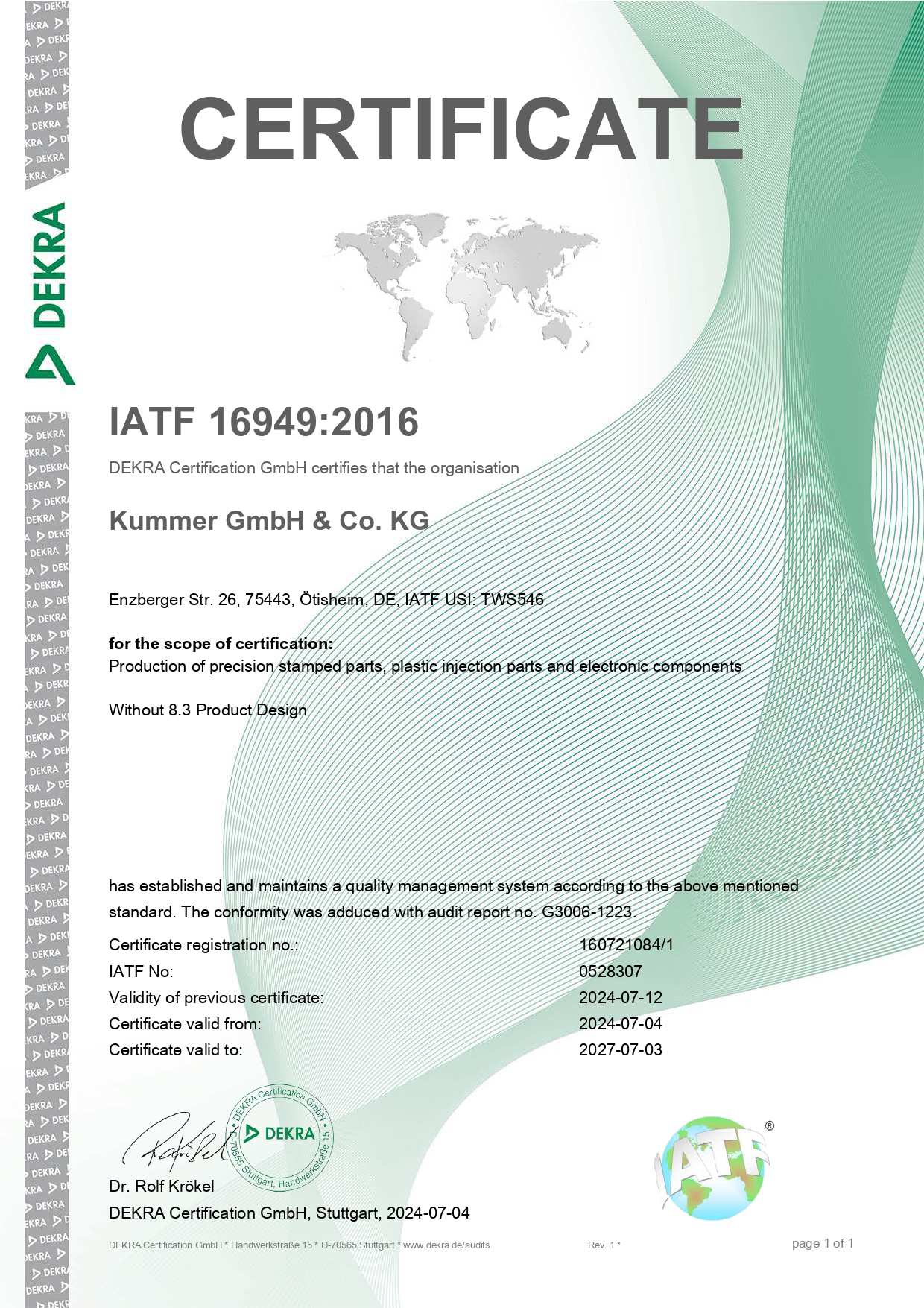

Kummer GmbH is a partner to the electrical, automotive and aerospace industries and is therefore subject to international quality standards. The company is certified acc. to ISO 9001:2015 and IATF 16949:2016 and furthermore has a certified environmental management system acc. to DIN EN ISO 14001:2015 and an energy management system acc. to DIN EN ISO 50001:2018. Through the promotion of individual strengths, we increase the expertise of our experts and the motivation of the whole team. In association with other companies, we are partly responsible for the creation of the "Stanztec" specialist trade fair for toolmaking and stamping technology in Pforzheim.

Click on the picture to download our Kummer "One-stop shop" brochure.

Kummer as a development partner – the advantages at a glance

- Full-service provider for toolmaking, stamping, injection moulding and assembly technology

- Comprehensive materials expertise – in plastic, metal and non-ferrous metals. Stamping and overmoulding in a single process

- Own toolmaking and development department for consultation and realisation of complex project requirements

- 40 years of experience with precision stamping of small and large-scale series.

- Production of complete assemblies in a closed process sequence.

Kummer as a development partner – the advantages at a glance

- Full-service provider for toolmaking, stamping, injection moulding and assembly technology

- Comprehensive materials expertise – in plastic, metal and non-ferrous metals. Stamping and overmoulding in a single process

- Own toolmaking and development department for consultation and realisation of complex project requirements

- 40 years of experience with precision stamping of small and large-scale series.

- Production of complete assemblies in a closed process sequence.

Click on the picture to download our Kummer "One-stop shop" brochure.

Our quality control is naturally certified to the prevailing ISO 9001:2015 and IATF 16949:2016 also includes measuring microscopes, hardness testing facilities, instruments for roughness depth measurement, microsection creation and insertion and pull-out forces for the EloPin®. In addition, the company has equipment for the qualification of products acc. to automotive standards.

The interplay of experience and modern production technology is decisive in the construction of tools. This forms the basis for the subsequent series production and at Kummer precision and quality are equally prioritised in order to ensure large-scale series characterised by a reliable function and free of errors.

Continuous testing, further development of technical standards, thorough supervision of our production processes, and careful checking of the finished components ensure that we meet the highest quality requirements.

We are a family-owned and managed company and are especially committed to the people of the region and their environment. A certified environmental management system acc. to DIN EN ISO 14001:2015, and an energy management system acc. to DIN EN ISO 50001:2018 verifiably document that environmental awareness at Kummer is not an empty promise, but is instead reality.

All production processes are subject to strict ecological criteria and adjusted for maximum environmental sustainability. This includes the protection of the life and health of our employees, the careful use of resources, the thorough processing of waste water and the comprehensive recycling of waste material materials. We have formulated our principles regarding environmental protection, energy conservation and careful use of resources in our company policy, which is available on request.