injection moulding

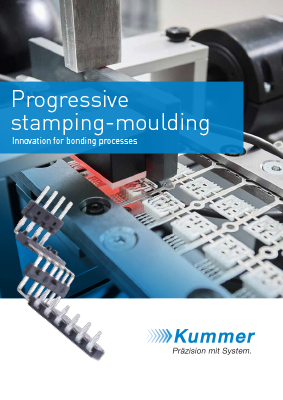

Progressive injection moulding is the further development of the known reel-to-reel process. It combines two production steps in a single machine: the processing of the stamped strip and partial overmoulding up to the finished component

Progressive injection moulding was developed by the Kummer GmbH company approx. 20 years ago. Today this process stands for high process reliability, increased economy and higher quality. This is based on the power of innovation and over 40 years of production experience.

The core idea of progressive injection moulding is to use the clamping force of the injection moulding machine to also carry out forming processes. The result is a fully automated production process which enables the forming process at almost no additional cost.

In the progressive injection moulding process, the following working steps are combined in a closed process:

- the mechanical processing of the lead frame,

- which is fed via an automated process (stamping, bending, etc.),

- and complete or partial overmoulding with plastic

The component is therefore stamped, bent and overmoulded in a closed process. Optical and electromechanical sensors integrated in the machine continuously monitor the process and quality of the component.

The core idea of progressive injection moulding is to use the clamping force of the injection moulding machine to also carry out forming processes. The result is a fully automated production process which enables the forming process at almost no additional cost.

In the progressive injection moulding process, the following working steps are combined in a closed process:

- the mechanical processing of the lead frame,

- which is fed via an automated process (stamping, bending, etc.),

- and complete or partial overmoulding with plastic

The component is therefore stamped, bent and overmoulded in a closed process. Optical and electromechanical sensors integrated in the machine continuously monitor the process and quality of the component.

Material: PET GF35 / 200,000 pieces

Special feature: ELO-Pin overmoulded on the stamping strip without automation

Material: PA66 6 GF30 / > 5 m pieces

Special feature: tool with 16 parts per shot, 2K overmoulded, 3 times folded connector without metal connection to the strip

Material: PBT GF 30 / 1.5 m pieces

Special feature: coined square pin 0.6 x 0.6 mm with feed directly from the stamping strip, overmoulded in the lead frame

Material: PBT GF30 / > 500,000 pieces

Special feature: 2K overmoulding on the stamping strip. Double row of pins on the stamping strip clipped and fully overmoulded

Material: PA66 GF35 / > 100,000 pieces

Special feature: strip with width of 230 mm electroplated, part bent on the strip and overmoulded

Material: PA66 GF35 / > 100,000 pieces

Special feature: strip with width of 230 mm electroplated, part bent on the strip and overmoulded

Click on the picture to download our "Progressive injection moulding" brochure

- higher quality and process reliability through a closed production process

- fully automated process without investment costs for an expensive automation cell

- improved economy as a conventional reel-to-reel process

- high delivery reliability. If the machine fails, the complete tool can be easily transferred to a second standard machine.

- forming process almost without additional costs through use of the clamping force of the injection moulding machine for the forming process.

- higher quality and process reliability through a closed production process

- fully automated process without investment costs for an expensive automation cell

- improved economy as a conventional reel-to-reel process

- high delivery reliability. If the machine fails, the complete tool can be easily transferred to a second standard machine.

- forming process almost without additional costs through use of the clamping force of the injection moulding machine for the forming process.

Click on the picture to download our "Progressive injection moulding" brochure

Innovative technology results in process reliability

The core idea of progressive injection moulding is to use the clamping force of the injection moulding machine to also carry out forming processes. The result is a fully automated production process which enables the forming process at almost no additional cost.

Innovative technology results in process reliability

The advantage of progressive injection moulding is that it only requires a single tool for the complete process. The result is that tool changeover times and machine downtimes are considerably reduced. Furthermore, the machine can be universally used. Therefore, the machine can be set up for a different product simply by changing the tool. This serves to reduce the costs per part.